When the world’s headlines start to buzz about a “monster surge” in electric‑mobility, a lot of people picture sleek, silent scooters zipping past traffic, or city commuters swapping car rides for battery‑powered bikes. The trend is real, and it’s driven by an often‑overlooked hero of modern electric transport: the reducer gear motor. In this article, we’ll look at how the current electric‑vehicle (EV) boom—highlighted by the latest news on accelerating global e‑mobility and sustainability commitments—puts this humble component into the spotlight.

News outlets across the globe have been reporting on a new surge in electric scooter and e‑bike sales. The International Energy Agency’s latest transport report announced a record penetration of battery‑powered two‑wheelers in 2024, while social media memes about “motorized mopeds” have reached viral status. Cities are sprouting charging stations, surprise scooter‑parking zones are popping up, and governments are offering subsidies for clean‑mobility purchases. The result? A market that could expand to 120 million e‑mobility units worldwide by 2030.

This trend isn’t just hype. It’s a response to rising fuel prices, stricter emissions regulations, and an increasing appetite for shared‑mobility solutions that fewer people can afford. As the global community looks to cut carbon footprints, the electric scooter and e‑bike have become the front‑line allies in urban sustainability campaigns.

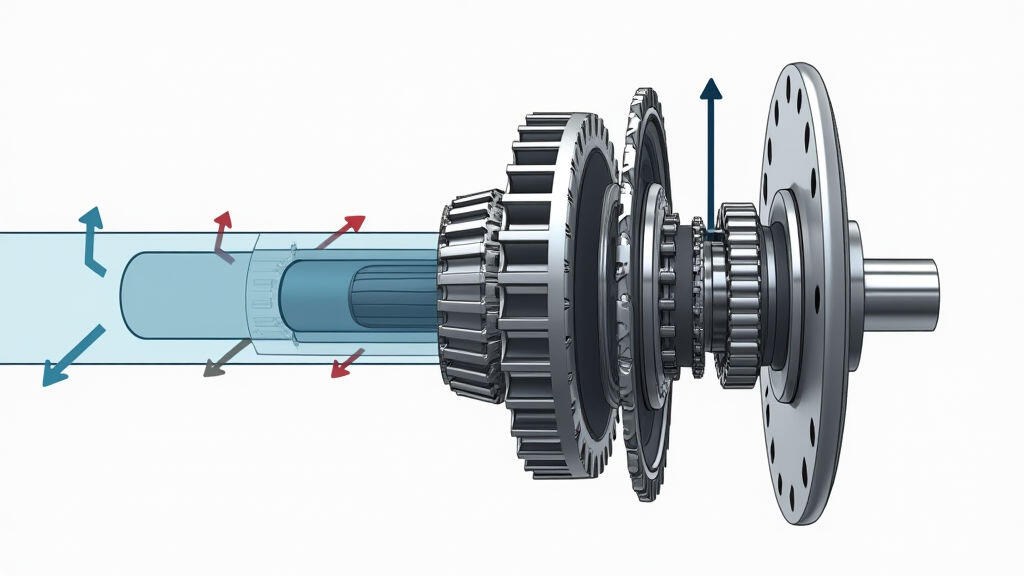

While all we see in the street is the beautiful, silent speed of an electric scooter, behind the curtain lies a marriage of motors and gear reducers that makes modern e‑mobility possible.

Power and Control

A direct‑drive motor, though efficient, cannot easily deliver the torque needed for rapid acceleration or steep climbs. Enter the gear reducer: by stepping down the motor’s high RPM to a lower, more useful speed, it boosts torque up to ten times while keeping the current low. This balance is essential for scooters that need to burst up a hill in seconds and then cruise comfortably on flat urban roads.

Durability in Urban Resilience

City scooters face potholes, jumps, and sudden stops. Unlike conventional cart wheels, gear reducers are enclosed and protected from the elements. They reduce vibration and mechanical stress, lengthening the motor’s lifetime and keeping the ride smooth—an attribute that bikesellers highlight in their marketing material.

Compactness and Efficiency

A gear motor’s packaging is tailored for the tight spaces of a scooter’s frame. By squeezing a powerful motor into a small footprint, manufacturers reduce overall weight and keep battery packs lean. This compactness is the reason why e‑bikes can be just as agile as their gasoline‑powered cousins, yet deliver a quiet, emissions‑free ride.

Manufacturers like Bosch, Brose, and BMS are already pushing the envelope with nano‑lithium‑coated components that further reduce friction and increase the energy conversion rate. For the e‑bike and scooter market, the reduction scope—from 3:1 to 7:1—provides an ideal trade‑off between peak power and battery efficiency.

With governments offering rebates, ride‑sharing apps integrating electric scooters, and urban planners cutting lanes, the demand for reducer motors is on the rise. Many scooters in the U.S. market already come equipped with gear ratios that maximize battery life for 30‑kilometer trips—perfect for the “last mile” transport that drives city commuting.

In Asia, Indonesia’s surge in motorcycle‑sharing platforms is one of the largest markets for gear motors. As the country’s cities grow denser, scooters are the clear answer—fast enough, small enough, and now efficient enough thanks to improved reduction technologies.

Meanwhile, Europe faces an intriguing statistical curve. The European Commission’s “Fit for 55” emissions target pushes for a 55 per cent cut in CO₂. The scooter’s carbon profile is so minimal that its contribution to the EU’s zero‑emission future becomes a case study in supply chain optimization.

What’s next for gear motors in the electric mobility arena? The answer lies in adaptive reduction devices—gear systems that can shift ratios on the fly, driven by AI sensors that monitor speed, load, and terrain. Imagine an e‑scooter that ‘learns’ your route and automatically selects the optimal torque profile for each hill, saving battery life.

Another frontier is the integration of regenerative braking into gear reducers. Hooked into a closed electric drivetrain, the gear can assist in capturing kinetic energy during downshifts, feeding it back into the battery whenever the rider slows or descends. This synergy between motor, gear, and controller could push range expectations beyond the current 60‑kilometer plateau.

Moreover, the shrinking size of gear motors complements the trend toward modular city infrastructure. Battery‑swap hubs, where whole power packs can be exchanged cheaply, rely on standardized reduction units that carry a certain torque/size profile, keeping the whole ecosystem simple and upgradable.

The electric‑mobility boom is more than an environmental punch; it’s a reshaping of urban geometry, a new chapter in supply‑chain sustainability, and an impetus for cleaner air. The reducer gear motor, though often unheralded, stands as the critical enabler that transforms small, silent motors into reliable, high‑torque powerhouses.

From hobbyist scooter builders to large‑scale ride‑sharing fleets, the demand for sophisticated, efficient gear reductions keeps escalating. With the advent of AI‑driven adaptive systems, integration of regenerative technologies, and the rapid expansion of the global e‑mobility market, the promise of the reducer motor is set to swell just as the electric scooter climbs every city block.

In the end, every time you see a quiet but spirited scooter glide past, remember that tucked inside its chassis is a small yet mighty gear motor, quietly turning the key to sustainable, urban freedom.

Leave A Reply

Your email address will not be published. Required fiels are marked